GET TO KNOW US

We are

Seco Industries, s.r.o.

We are a Czech manufacturing company from Jičín. We are engaged in foundry, casting machining, toolmaking and development and production of garden tractors and mulchers. We are one of the leading companies on the Czech industrial market with long-standing cooperation with customers from all over the world.

COMPANY HISTORY

Seco Industries, s.r.o.

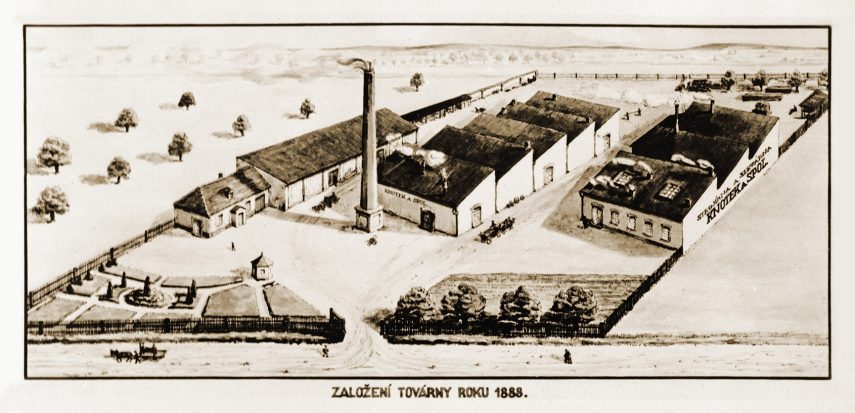

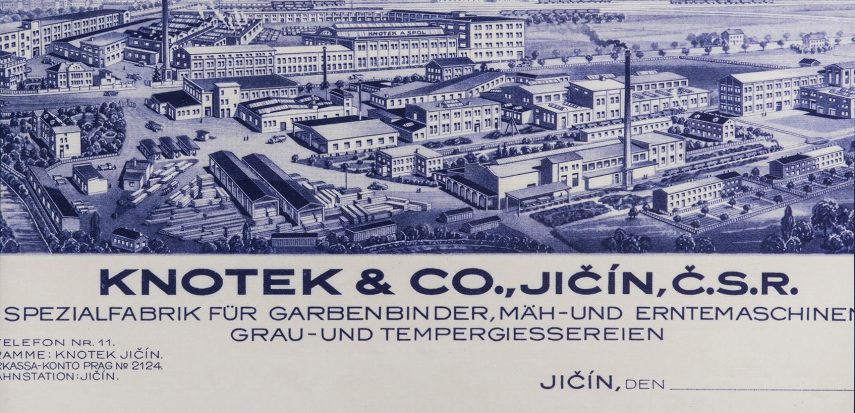

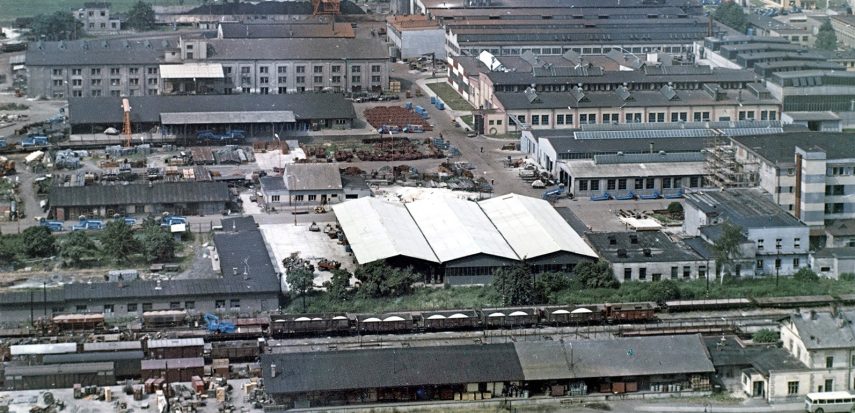

The origins of the company date back to 1888. At that time, František Knotek established a factory in Jičín for the production of farm machinery and tools. In 1913 the company expanded to include a foundry for malleable iron. The company was nationalised in 1945 and five years later the company was renamed to Agrostroj Jičín, national enterprise. Its new specialisation was the production of machines for harvesting cereals, forage crops and root crops. Production continued to grow and the company expanded.

In 1954, one of the most modern foundries of that time was part of the production. In 1960, a machine hall was added for the assembly of heavy agricultural machinery such as beet harvesters, ploughs, potato graders, etc.

7 years later, a melting shop with electric induction furnaces and a machining line for the production of cylinder liners for internal combustion engines were added. The product range has been expanded to include mowing and construction machines, six-row self-propelled trimmers. However, the development continued and other products from Agrostroj Jičín were successfully sold on the market.

In 1994, the company was privatised. In the same year, production of garden tractors for mowing grass began. Subsequently, the name was changed to AGS Jičín a.s. and later to Seco GROUP, a.s. After the ownership changes were settled, the company was renamed to Seco Industries, s.r.o. in 2017. There has been a large increase in investment in production technology and human resources, as well as in production and warehouse space. The distribution of garden tractors and mulchers with the new SECO product logo and the construction of a new machining hall with subsequent robotization of selected workplaces was launched.

We're going back in time...

1888

The year was 1888. It was then that the beginnings of our company were established with the founding of the Knotek a spol.

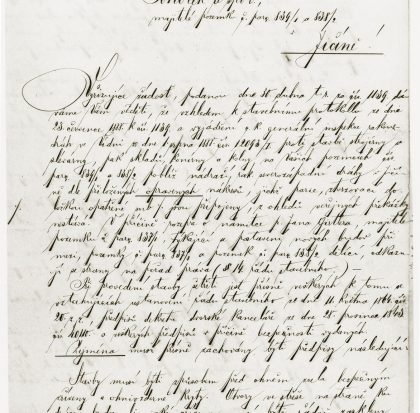

1888

Building permits for the construction of production facilities

1900

The founders of Knotek a spol. Sitting on the left: Antonín, on the right František Standing on the left: Václav, on the right Josef

1910

In 1910 a huge manufacturing company called Knotek a spol was already built in Jičín.

1915

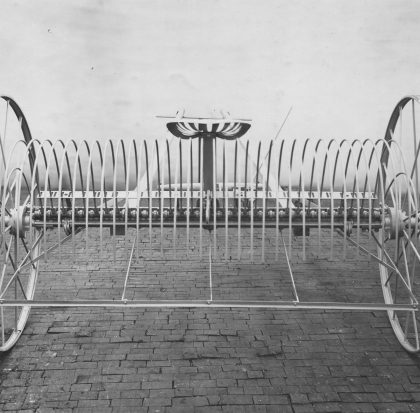

The first self-propelled mower was launched by the company in 1915.

1936

In 1936, they introduced the self-emptying raking machine, type FD.

1968

The business was booming, the company was growing. In 1968, the Knotek agricultural machinery production was already backed by a well-equipped complex, where many new agricultural machines were built to make work in the field and on the farm easier and more efficient.

1985

The twelve-row sowing drill adapter was a huge help. In the picture it is carried by a self-propelled machine MT6-045 from 1981.

1989

The first single-axle small tractor type MT7-032 was seen on the streets and in the fields in 1989.

1997

As time passed, the first small lawn tractor, the Starjet, was born in 1997 in the hands of experienced manufacturers. It was green in colour and sold quickly.

2002

The elegant Crossjet AC-92 SUPER took to the hilly turf road in 2002.

2018

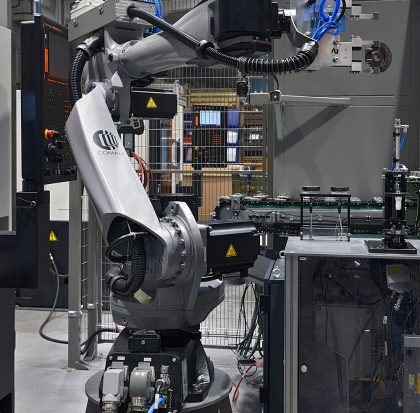

Robotic machining of castings.

2019

New machining workshop for castings.

2020

Showroom Garden tractors and mulchers

2020

MP 122D tractor for municipal services developed.

References

CAREER

Come and work for Seco Industries, s.r.o.

Fancy a change of job? Do you long for a place where you will be appreciated? Contact us! Take a look at the current vacancies. Maybe an interesting job opportunity has just opened up for you.